Smart Drainage System®

For over 48 years, Agri Drain has provided products and services to increase farm profitability while improving and protecting our valuable natural resources. Our water management products are used for in-field and edge-of-field agronomic and conservation practices such as drainage water management, sub-irrigation, saturated buffers, bio-reactors, tile outlet terraces, ponds and wetlands to conserve and improve water quality, increase yields and reduce soil erosion.

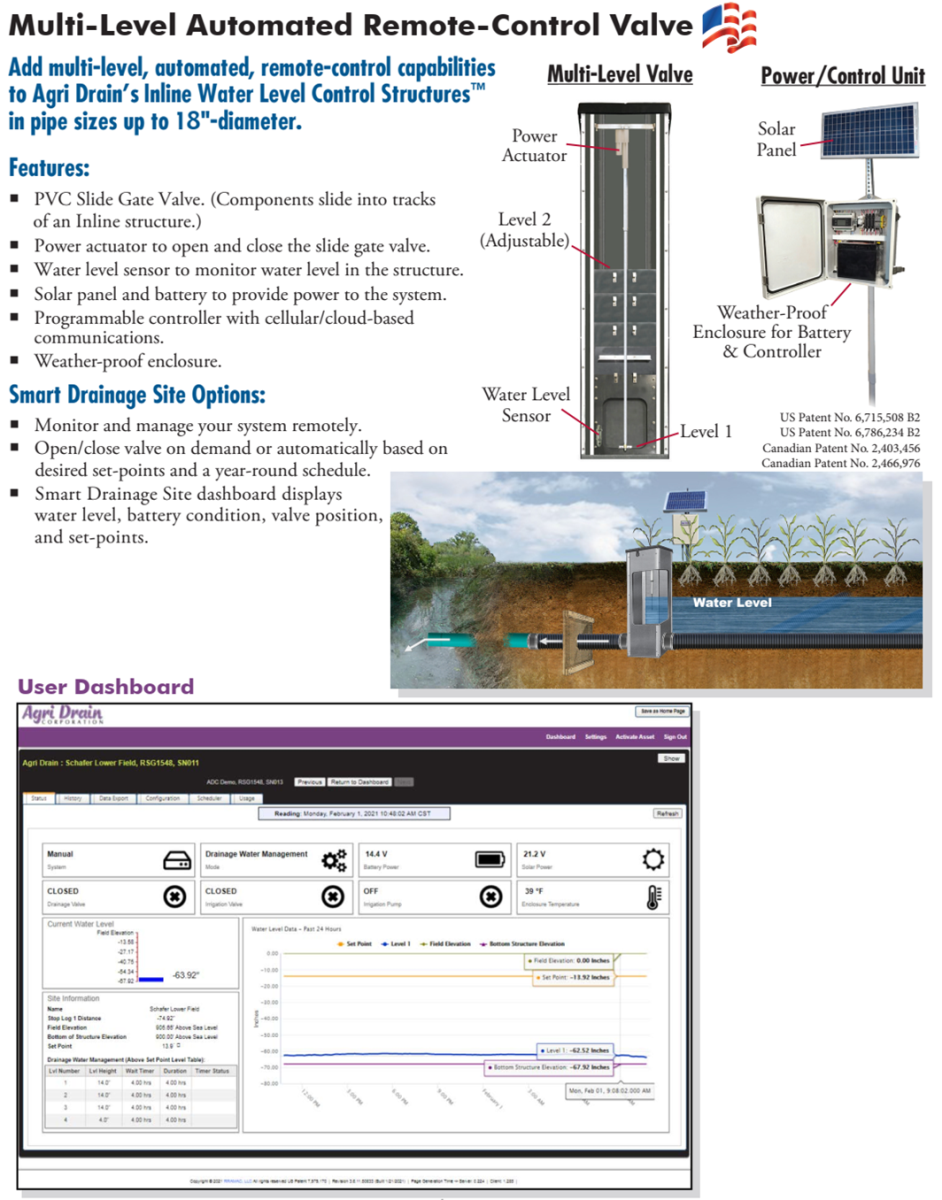

Agri Drain’s Smart Drainage System® gives users the ability to manage their drainage system, ensuring the proper moisture level for maximum yield, while reducing nutrient loss and risks associated with drought or excessive moisture. To preview our Smart Drainage Site Dashboard, click here.

Smart Drainage Site

Agri Drain’s Smart Drainage Site gives users the ability to program, monitor, and record site conditions from their cell phone, laptop, or tablet. The Smart Drainage Site allows users to send commands to open or close the valve within their structure, manage structure settings and set points, view valve status (open or closed), water level in the soil profile, flow rates, and battery level. Rain gauge, soil moisture sensors, and pump control can also be added. To preview our Smart Drainage Site Dashboard, click here.

2 & 3 Level Manual Valves

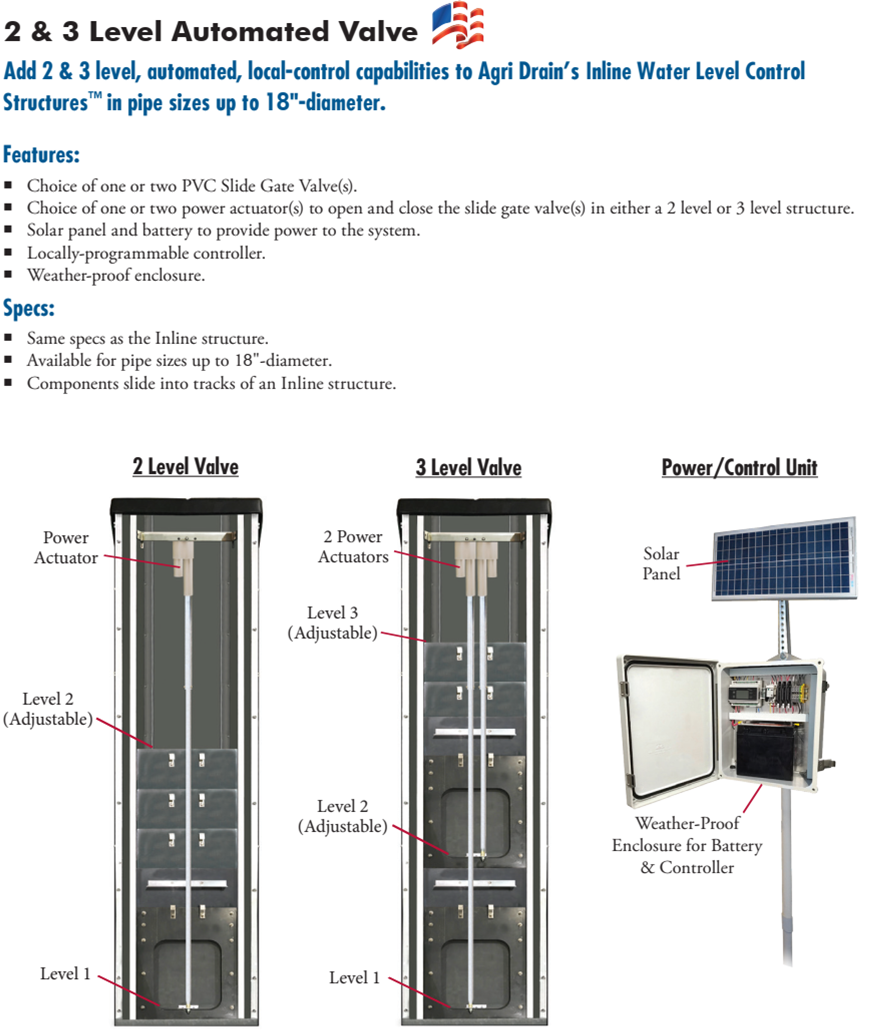

2 & 3 Level Automated Valves

Multi-Level Automated Remote-Control Valve

Article in Business Record's innovationIOWA Magazine: Agri Drain, Providing Common Sense Solutions to Complex Agricultural and Environmental Issues

Research Shows Yield Increase

“The effect of controlled drainage on crop yields was strongly dependent on management. Average response was a potential 10% increase in yields when controlled drainage is effectively managed.”

- R. Wayne Skaggs, North Carolina State University